January 2026

Refridgeration Deck

The Reefer Deck was one of the spaces that had not really been touched when heavy maintenance began in 1998. However, in February of 2004, that all changed. Gary Sheedy had been dreaming about the restoration of the reefer decks, ever since he reported aboard the SLATER in 1998. The Reefer Deck was space that we could have easily ignored and passed by. Tucked below the forward crew's quarters, with only one access, there was no reason for anyone to go down there. It made a good storeroom for electrical spare parts, but there was no need to restore it. Just keep the hatch dogged on tour days. But Gary was an "A" Gang electrician, and the reefers were his space, and this was important to him, so the plan become to restore it.

Gary’s fellow crew began to tackle one of the most difficult parts of that restoration: the replacement of the wasted deck. The whole section against the aft bulkhead had to be cut out and replaced, all while working in the harshest conditions amid the acid smell of flashing welding rod and burned metal. The water in the fire watch bucket has frozen solid. As Tim Benner cap welds the plate from above, he wondered, "Where's Sheedy?" As Gene Jackey pounded on the adjacent deck plate with a needle scaler looking for more waste and pinholes, he too wondered amid the din, "Where's Sheedy?" The replacement of the deck plate involved climbing through a tiny manhole to access the fuel oil tanks below. We have cleaned and ventilated them to make them safe for welding. From underneath in this tank, Doug Tanner back welded the deck plate, now the overhead from underneath. A red devil blower provided a flow of air, making it even colder. As another piece of hot molten metal arced down the back of his neck, he gritted his teeth and muttered, "Damn Sheedy."

By October, Barry Witte and Gary Sheedy finally had been forced to become deck apes. Gary was so tired of waiting for Tim to put a crew on the reefer decks chipping that Gary enlisted the electricians to do the job.

By January 2005, chippers Ed Whitbeck, Chriss Fedden, Jim Gelston, and David Hamilton had the Reefer Deck portside storeroom just about finished. By February, Ed Whitbeck was finishing up chipping and preparing for spray painter Kevin Sage to come in and spray it with white, to be done in March. In April, Gary Sheedy was back in the Reefer Deck and reassembled all the shelving he took out to repaint. In July, Gary enlisted Radioroom volunteer Joe Breyer to weld down in the Reefer and they worked down there repairing the overhead piping and installing an expanded metal cage. September saw Gary continuing work on all the expanded metal in the electrical storeroom off the Reefer Deck.

By April 2006, Kevin Sage and Jason Sherlock wrapped up painting the portside of the reefer deck which is the electrical parts storeroom. Summer of 2006, Gary Sheedy has tried to spend as much time as he can down on the reefer deck organizing and restoring his spare parts drawers. He almost completed work on the portside storeroom and began getting ready to reassemble the refrigeration compressors. 2006 closed out with Gary spending the last month scaling the refrigeration compressors and motors to get them ready for restoration. The portside electrical storeroom was now fully restored; deck painted, lockers shined, cabinet drawers labeled and parts stowed on shelves in a state where anyone can all find what they need.

In February of 2008, Gary Sheedy had been doing the final needle gunning and sandblasting in preparation for painting the space that spring. Stan Murawski joined him doing insulation work down there. March saw more sandblasting. Gary Sheedy brought a whole pile of copper and brass piping out of the reefer deck, as well as all of the wooden deck gratings from down there. In June, Gary was actually making visible exciting progress in the Reefer Deck. He had been polishing up the gas cylinders and copper piping and heat exchangers.

Starting off 2009, Gary continued to wile away his Saturdays polishing brightwork on the reefer deck. He then was working on the condensers, and planned to be putting the rigging together to remount them in the overhead in the Spring of 2009. By April, Gary had reached a major milestone on the reefer deck. With little fanfare, he hoisted the second bronze condenser back into its brackets in the overhead and was then working on the motor controllers. The space continued to progress as Gary painstakingly restored each piece of brass and copper one piece at a time. As a commercial refrigeration technician, Gary spent a lot of time during the workweek in motels. He usually carried part of the reefer deck with him and works on his hobby as hotel rooms became his workshop.

In June 2009, Gary finally found a helper. New volunteer Wiley Johnson was an Air Force vet who spent his Saturdays helping Gary move the project along, chipping, doing brightwork, and refinishing the wooden reefer gratings. Gary had most of the brightwork finished and was working on restoration of the motor controllers, compressor bases and gauge panels. He even started collecting vegetable crates for his anticipated reefer display. In August, Gary was the chief beneficiary of the most recent trip to the LSM45, where he received dogs for the reefer doors and several valves and pressure switches identical to the ones he was missing down there.

But in 2009, as autumn drew to a close, Gary felt like he was turning the corner and the end was finally in sight. All the bulkheads had been chipped and painted white. The deck had been chipped and painted red. All the pipe insulation has been repaired and painted white. The compressor bases were chipped and painted metallic silver gray and have been remounted. The first compressor had been restored to like new condition and remounted. Missing parts and valves were obtained from the LSM-45. All the gauges, instrumentation and piping had been cleaned, restored and shined and were in Gary’s home shop awaiting installation. He was finally seeing the light at the end of the tunnel after almost nine years. The place would be a showpiece and there wouldn’t be any place on the SLATER that could compare to Gary’s exquisite restoration job. And there was even plans to restore the reefers. Gary had spent the last nine years collecting period looking vegetable crates, fruit crates and boxes for his reefer display. One section will be his display space, one cooler would continue to house Rosehn Gipe’s financial records, and one cooler would be Gary’s personal tool room. There was just one little problem, an annoying little stream of water that would occasionally appear from pinholes in the bulkhead between the coolers and the machinery flat. That, coupled with the fact that the coolers always seemed a little damp, didn’t seem like a big deal. A lesser man would have ignored it. But Gary Sheedy isn’t a lesser man, and Gary Sheedy couldn’t ignore it. He just had to find out where that water was coming from. So, with the end in sight and the restoration of the reefer decks coming down to remounting the gages, polishing the copper and hanging the pinups, Gary went into the starboard cooler and started ripping out the false decking. Carefully of course, so it could be replaced. Carefully drilling out one pop rivet at a time. When he had enough of the decking out to slip his hand in there, what he felt wasn’t encouraging. The false deck contained about six inches of fiberglass insulation. Very wet fiberglass insulation. Gary, the perfectionist who had been working on this project for nine years, dutifully removed all the sheet metal decking in the starboard cooler and began pulling out the sodden fiberglass by hand. It was all bagged and hauled ashore to the dumpster, sack full after sack full. The corrosion revealed under that fiberglass was a bit unnerving to say the least. The ship lays with about a one degree list to starboard because the Greeks removed the donkey boilers and the evaporator, all located on the portside in B-2. Thus the heaviest amounts of water had been lying against the starboard shell plating in the reefer, right below the waterline, with the fiberglass acting as a big damp sponge. That shell plating was only a quarter-inch original build. The idea that the damp fiberglass had eaten through the shell plating at the waterline seemed like a very real possibility. Thus, it was with great trepidation that Gary rigged a dehumidifier and waited for the results. Over the course of a week the compartment slowly dried out, and the water did not return. It looked like Gary have been spared for now. He then enlisted Chris Fedden and Ron Mazure to help him needle gun the deck, with instructions not to go at the side shell plating with anything heavier than a putty knife. After some severe beating with a needle gun, the deck turned out to be solid, with no holes. No such pressure was applied to the side plating. A coat of Corroseal, then primer would be placed on, and then Gary would reinstall the false deck. While the scaling was going on in the starboard cooler, Gary set about to tackle the forward centerline cooler. The crew hauled twenty boxes of Rosehn’s financial records up to the berthing space. Gary set about removing the false decking there, following the same process of removing, bagging and disposing of the fiberglass, and then drying the space out. It wasn’t as sodden as the starboard cooler, but it was far from dry. After a week under dehumidification the space was bone dry. Now that the worst case scenario, pin holes at the waterline, had been proven unfounded, there remained a couple of theories as to where the water had come from. One is that it’s a result of storing our winter drinking water in the bunk lockers in the CPO mess. Occasionally the jugs would leak, flooding the bunk lockers. The water then found its way to the magazine below, and then through pinholes in the bulkhead to the adjacent reefer deck aft, saturating the fiberglass. Erik Collin partially solved the problem when he put flat pans in the lockers to hold the water jugs, but several gallons had leaked through over the previous ten years. Then there’s the possibility that most of the water was a result of fighting the fire in 2006. A lot of water flooded the starboard side lockers in the berthing space above and there’s a good chance that some of it found its way down to the reefers. Maybe condensation from the years she was in service? And who knows what else may have happened when she was in Greek service. The net result for Gary was that his completion date for the reefers had been pushed back several more months. He would go through the same process on the port side cooler and the centerline entry way, neither of which borders on shell plating. Once again, the fine film of rust dust that results from needle scaling had coated all of Gary’s polished piping and paint work.

January 2010, down on the reefer deck, they finished chipping the centerline and starboard reefer deck and there was one day that was actually warm enough that Don Miller and Walt Stuart got to Corroseal the section. Now all there was to do was wait for it to get warm enough again to paint. That came in February, when it reached forty degrees again and Don Miller and Earl Herchenroder went down to put yellow chromate over the Corroseal in two of the reefers. Due to the cold, it’s takes the chromate a little longer to dry than normal, which is about two weeks.

In August 2010, we welcomed the Chief Petty Officers from the Nuclear Power Training Unit in Ballston Spa. Two selectees went to work down on the reefer deck and scaled and Corrosealed the deck of the last reefer that Gary was planning to restore. Don Miller and Walt Stuart then came and primed the space. The preservation was done, and it was time to start putting the reefer deck back together. In October, Gary and several unnamed helpers completed the stabilization and preservation of the steel under the false deck in the reefers; and the reefers were all back together. Gary then was putting his effort into the fine detail of the refrigeration compressors themselves, and one could now see some visible progress. To finish what had been a busy year in the Reefer Deck, both restored refrigeration compressors had been installed, as well as the electric motors. All the belts were back in place and Gary was in the process of running the wiring for the motors and controllers.

In January of 2012, Gary Sheedy and Dave Jeffries continued their work in the Reefer Deck, where they had been all winter. Gary was very close to putting up the gauge board and completing the space. He then moved his effort into the portside reefer where he had begun restoration of that space. He and Dave removed all the cooling coils and are refinishing and polishing them. By April, Dave Jeffries completed cleaning and polishing all of the refrigeration coils on the portside reefer space. Gary Sheedy completed painting the space, and it looks like the day she came out of the builder's yard. By July, Gary Sheedy had gotten his electrical storeroom down below the reefer deck all cleaned out and organized so he could find what he needs when he needs it. In September, Gary hit a real milestone with the installation of the gauge board and the log desk as well as the lampshades and electrical box covers. In December, Gary cut out all the steps on the reefer deck ladder and replaced them with new steps that were fabricated last winter. Then he went to work sandblasting the paint off the copper cooling coils in the centerline reefer.

Having finished his sandblasting of the starboard chillbox, Gary Sheedy set about polishing the copper refrigeration cooling coils in February 2013. He then began the process of buffing out the copper. By April, Gary Sheedy completed restoration of the starboard chill box and promptly locked it up so nobody would start using it as a storeroom again. He then continued restoration of the original wood gratings and began the process of securing all the cable straps and repainted the deck.

September 2013 was the unofficial opening of Gary Sheedy’s restored reefer deck. Only when one goes down that ladder can one appreciate the thought, planning, time and effort that had gone into this painstaking restoration. The space is complete with replica fruits and vegetables, a produce scale, period food crates, and stenciled burlap sacks. Guides started taking small groups of visitors down on a limited basis. Of course, we acknowledge the contributions of Dave Jeffries, Wiley Johnson, and all the other volunteers who helped Gary along the way.

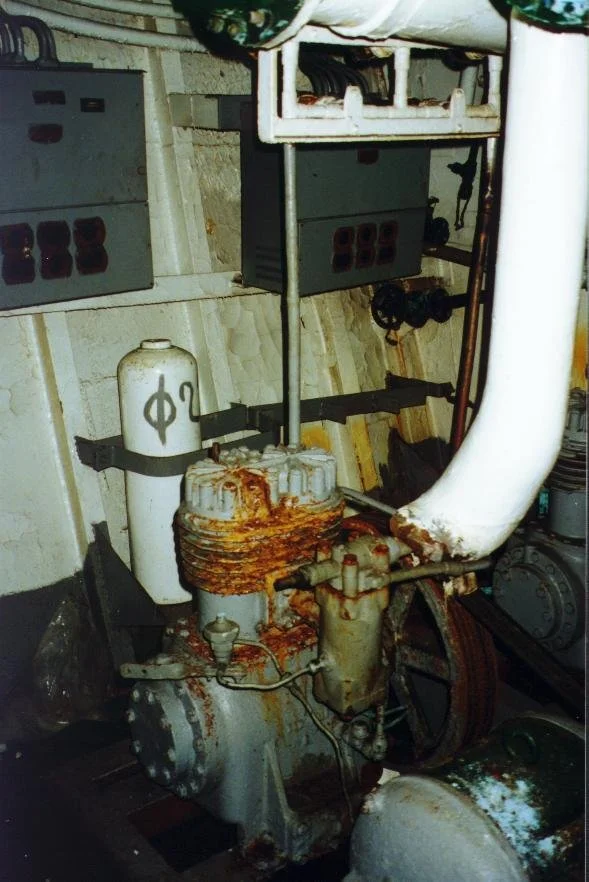

Compartment C-203L before restoration. It was mainly used as storage.

Compartment C-203L before restoration. It was mainly used as storage.